There’s no use crying over spilled beer. Not that it’s ever stopped me before. And I’m only likely to spill one bottle’s worth of something delicious but fairly ordinary. Jace Marti, Assistant Brewmaster at August Schell Brewing Company in New Ulm, had reason to throw a full-blown temper tantrum when nearly five barrels of a single batch special edition beer leaked out of the 78-year-old cypress wood tank where it had been aging for seven months.

There’s no use crying over spilled beer. Not that it’s ever stopped me before. And I’m only likely to spill one bottle’s worth of something delicious but fairly ordinary. Jace Marti, Assistant Brewmaster at August Schell Brewing Company in New Ulm, had reason to throw a full-blown temper tantrum when nearly five barrels of a single batch special edition beer leaked out of the 78-year-old cypress wood tank where it had been aging for seven months.

One Sunday morning last winter, during a week-long stretch of subzero temperatures (which one, right?), Marti went to check the fermentation in one tank only to find his specialty Berliner Weisse drizzling out another. The cypress wood dried out in the extreme cold and cracked. The tank could hold 143 barrels and had around 140 barrels inside when the leak sprung. The small spot was visible the moment you set foot in the cellar door and Marti pointed it out to me saying, “That was a bad day.” Maybe I imagined the glean of unshed tears in his eyes…maybe.

One Sunday morning last winter, during a week-long stretch of subzero temperatures (which one, right?), Marti went to check the fermentation in one tank only to find his specialty Berliner Weisse drizzling out another. The cypress wood dried out in the extreme cold and cracked. The tank could hold 143 barrels and had around 140 barrels inside when the leak sprung. The small spot was visible the moment you set foot in the cellar door and Marti pointed it out to me saying, “That was a bad day.” Maybe I imagined the glean of unshed tears in his eyes…maybe.

Marti is a sixth generation member of the Schell family, so craft beer is in his blood (by genetics and consumption). His father Ted took over running the brewery in 1985 and since that time, Schell’s has brewed over 100 different varieties of German craft beer. His brother, Kyle, is the mastermind of Schell’s sales, while their brother, Franz, maintains the picturesque grounds surrounding the brewery. In a family with 154 years of brewing history, do you suppose beer loss would constitute disinheritance?

Brewing beer is so much a part of the Marti family’s daily lives that even Easter dinner doesn’t pass without talk of the business. And business has been good enough to allow Schell’s to undertake a multimillion-dollar expansion project focused on quality instead of quantity. From water treatment to warehousing, almost no process will be untouched by the quest to produce the best beer possible. By no means, though, will the Schell’s brewery be full of brand new, state of the art brewing equipment. In fact, older equipment is sometimes best suited for the job.

The leaky tank was one of ten built for lagering in 1936 inside what is called the “E cellar” of the brewery. Back then, the whole room was kept cold to store lagers for several weeks until they were ready to be filtered and packaged. The tanks served their purpose well until they were replaced in 1993. Eight of the tanks were moved off site to a “top secret” location. The remaining two tanks sat empty until 2008 when Marti decided to use them for brewing Schell’s Noble Star series.

It took five years to get the tank into usable condition. The process included using water to get the wood to swell up, hiring a dry ice blasting company to remove the thick pitch lining, and brewing a sacrificial beer to sit inside the tank for a few months. After the final cleaning, Star of the North was put in the tank and then released in 2013 as the inaugural beer in the series.

The other cypress tank on site has since been restored, and both are now exclusively used for brewing sour beers. Marti, a true beer geek’s brewmaster, explains why these particular tanks are so well suited for sours:

The other cypress tank on site has since been restored, and both are now exclusively used for brewing sour beers. Marti, a true beer geek’s brewmaster, explains why these particular tanks are so well suited for sours:

They are made of cypress, which has a neutral flavor profile, and they are very old, so they don’t impart any wood flavor into the beer. Wood is naturally porous, so it allows small amounts of oxygen to seep into the beer, which is good for Brettanomyces. The porous surface of the wood also allows the Brettanomyces and lactobacillus to embed in the wood grain, which will develop into a more complex microflora over time and hopefully produce some unique flavors in the beers.

A tank being perfectly suited to hold sours is important, but not more important than actually being able to hold beer. As the Berliner Weisse continued to leak out of the tank, Marti tried to stop the leak outside with some of the pitch that was removed from the inside. When that didn’t work, he moved most of the beer into a stainless steel tank to slow the leak. The tank was sprayed with water continually for nearly two weeks before the leak finally stopped (and there was much rejoicing).

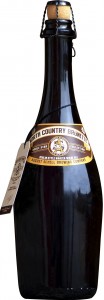

The resulting beer is the third beer in Schell’s Noble Star series called North Country Brunette. It is very tart and dry with a fine, rounded acidic profile and a malty, spiced fruity character. North Country Brunette left the brewery last week, so start looking for it in stores today. The Schell’s beer locator will help you find it.

The cypress tanks will continue to be used solely for brewing sour beers, and a Berliner Weisse aged on cherries will be available this summer. Marti likes to come up with ideas for new beers after he’s had a few Schell’s brews, so you can rest assured that he’ll keep them coming.